Exciting and innovative

The CUE is the solution

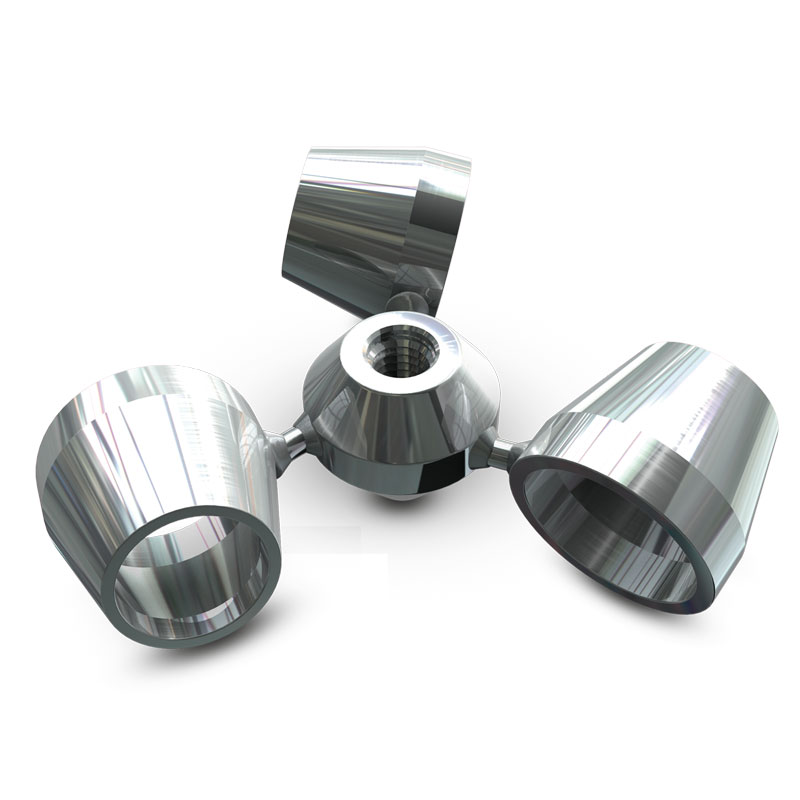

The CUE allows simple and energy-efficient agitating of sediments, even after the medium has stood or been stored for a long time.

The mixing element can prevent complex and expensive agitation processes during storage to avoid sedimentation, thus creating a significant energy and cost advantage.

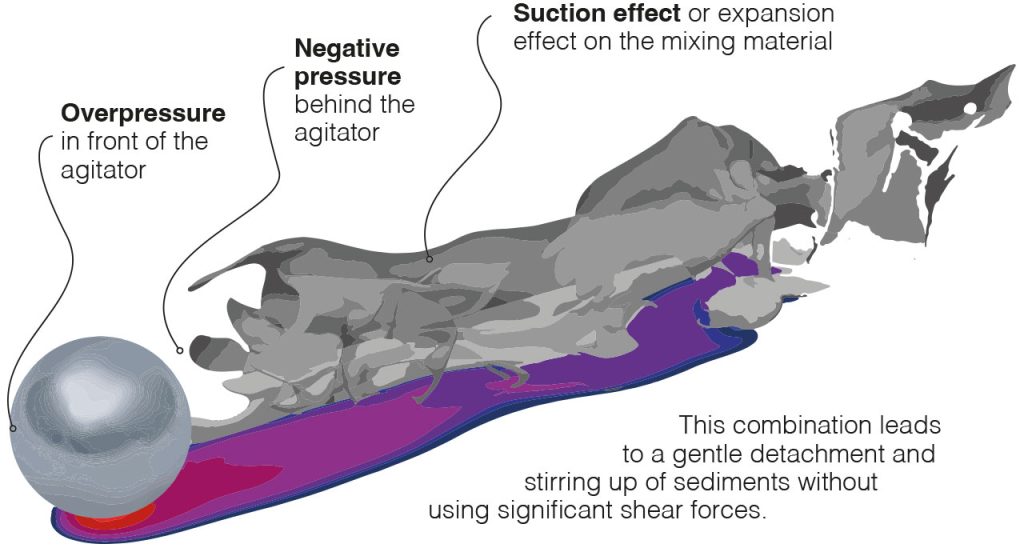

- The innovative geometry creates a suction effect behind the mixing element, which gently detaches the sediment

- The mixing element is placed without any spacing to the sediment

- The geometry prevents jamming in the sediment or clogging of cones

- Low operating speeds achieve an energy-efficient process

An innovation that pays for itself

Well thought-out, right down to the smallest detail

In suspensions mixing processes, sediments often form after a storage or standstill period, whereby the

formation of the sediment depends on the material properties of the media to be agitated.

The aim is to obtain a homogeneous mixture of liquid and the solid particles contained therein by agitating the sediment.

- 3-fold design of the impeller cones

- Standard version up to a impeller diameter of 650 mm

- Individual sizes also available on request

- Stainless steel 1.4301, 1.4404, 1.4571

- Tornado version for use in IBC containers

- Installation in combination with several stirring levels and residue stirrer

- Individual coatings for an extremely long service life

- Ground version with Ra<0.8 μm or Ra<0.4 μm

More information

Have you found what you’re looking for? We would be happy to show how you can benefit from using the VISCO JET® CUE based on your process requirements!

Similar products

You know about it and want to tackle it?!

… or we’ll call you back:

Nothing is as valuable to us as your time. That is why we are happy to prepare specifically for you. We will call you at your preferred time and clarify your questions. This is how we save your time and make your project successful with VISCO JET® solutions! We look forward to seeing you!