Relaunched

Redesign of a great product

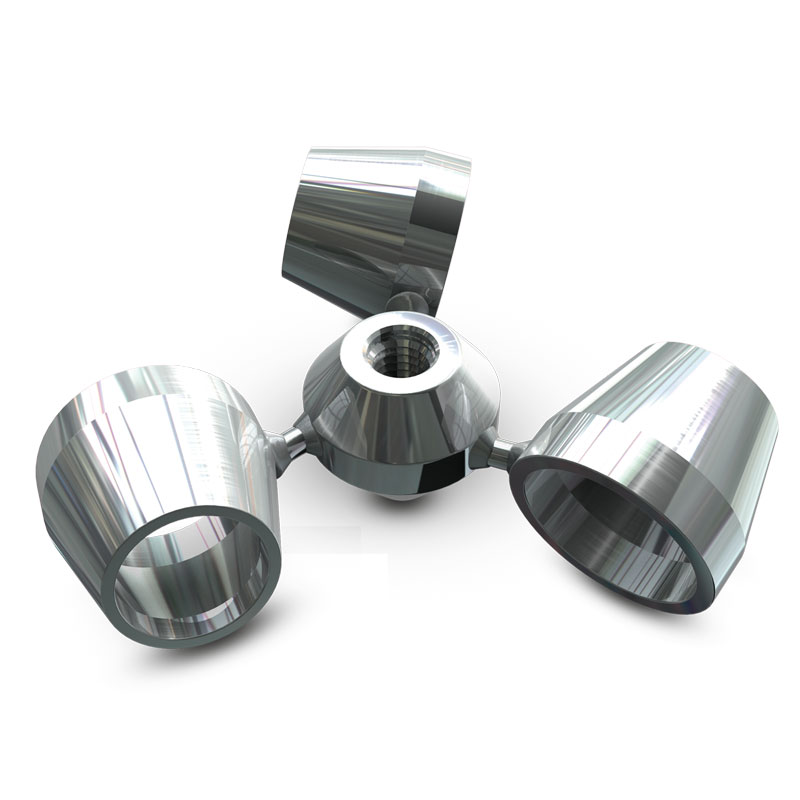

The VISCO JET® STEP³ is the new standard for side-entry agitators and enables our customers to achieve energy-efficient agitating through maximum conveying capacity, even with very large container heights.

The impeller thus makes it possible to improve the production process and obtain optimum product quality, even with large production quantities.

- Intrinsically dynamic agitator movements due to accelerated laminar flows at the cone outlet and turbulence at the cone inlet

- The stepped cones enable an optimum flow structure even at higher peripheral speeds

- The sophisticated design ensures optimum flow rates in the container

- Lower power requirement of the agitator (15 – 30 % less) without reducing the mixing action

Unbeatable for lateral installation

Well thought-out, right down to the smallest detail

Problem solver3

In many industrial sectors, tank installations use side-entry agitators.

This design has the following advantages:

- The investment costs for the tank are often significantly lower, as the tank lid design is easier and more cost-effective to manufacture

- Easier access to the agitator for maintenance

- More cost-effective agitator due to lower material costs for the shafts (especially for very high tank installations)

The challenge, however, is that these agitators have a significantly higher power requirement in order to achieve the appropriate flow rate and height for complete mixing in the vessel.

The STEP³ takes on precisely this challenge and achieves efficient mixing of the entire medium in the production tank with significantly lower speeds.

- 3-fold of the impeller cones with arrangement on different levels

- Standard version up to a impeller diameter of 2,000 mm

- Individual sizes also available on request

- Stainless steel 1.4301, 1.4404, 1.4571

- individual material according to customer requirements, e.g. Superduplex or Hastelloy

- Individual coatings for an extremely long service life

- Ground version with Ra<0.8 μm or Ra<0.4 μm

- Split version of the mixing element for easier insertion into the production tank

More information

Have you found what you’re looking for? We would be happy to show how you can benefit from using VISCO JET® STEP3 based on your process requirements!

Similar products

You know about it and want to tackle it?!

… or we’ll call you back:

Nothing is as valuable to us as your time. That is why we are happy to prepare specifically for you. We will call you at your preferred time and clarify your questions. This is how we save your time and make your project successful with VISCO JET® solutions! We look forward to seeing you!