Ingenious solution

The problem solver

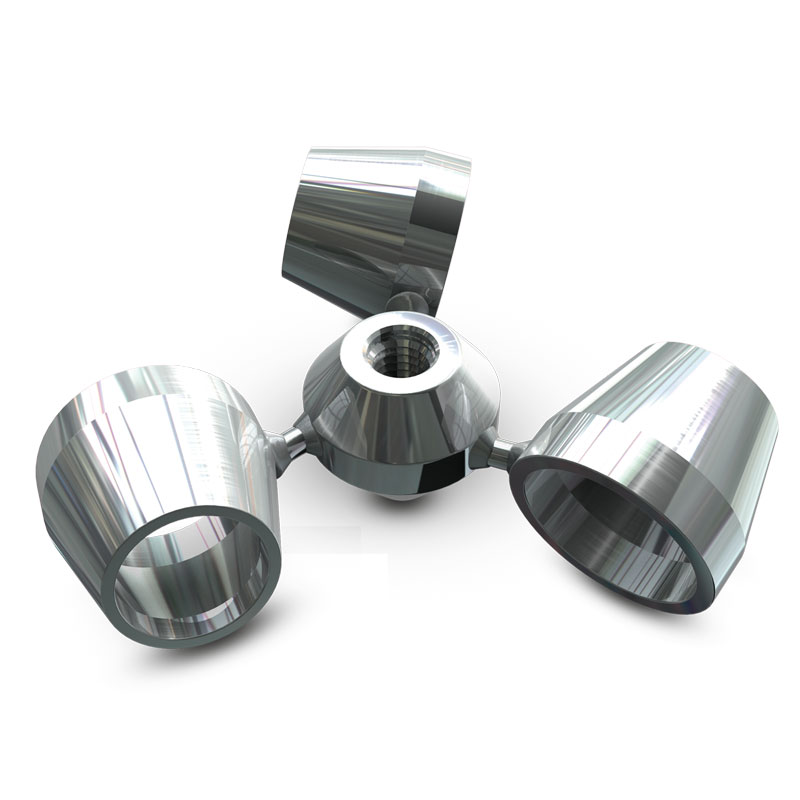

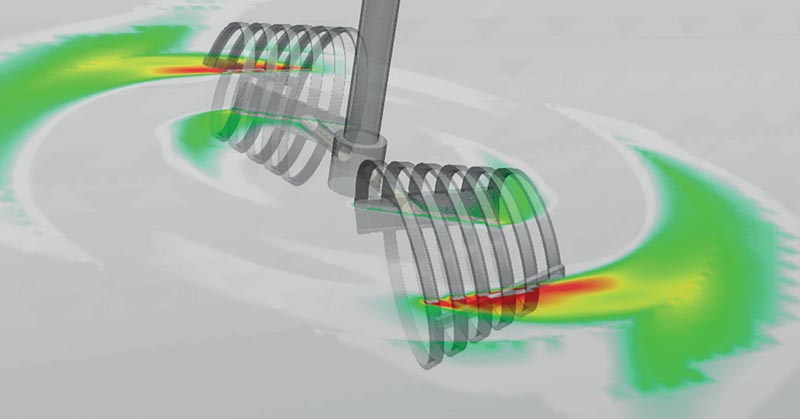

The VISCO JET® SPIRAL is the solution for homogenising highly viscous media and for efficiently suspending solids in liquid media.

- Can be used for media with a viscosity up to 100,000 mPas

- Self-dynamic mixing movements due to accelerated laminar flows at the cone outlet as well as turbulence at the cone inlet and between the spirals

- Axial and radial flow structure guarantees optimum flow rates in the tank, even with high viscosity of the product or with a horizontal tank structure

- Efficient mixing even at low peripheral speeds

- Rapid incorporation of solids from the surface into the product thanks to a sophisticated mixing element design

Highlights

Sustainable in every detail

The homogenisation of media with high viscosity is part of the manufacturing process in many industries, such as, for example, pastes in the food and cosmetics industry or the paint and coatings industry.

Even when solids such as powders or grains are agitated in evenly, e.g. in the area of plaster production, a successful agitation process is made more difficult by changing product properties.

If the agitating process is not optimally designed to meet the manufacturer’s requirements, this leads to various challenges in the production process.

Our VISCO JET® SPIRAL is the solution for these applications and offers a wide range of applications from laboratory scale to production tanks. Discover all the advantages of the VISCO JET® SPIRAL!

- 2-fold or 3-fold design of the impeller cones

- Standard version up to a impeller diameter of 2,000 mm

- Individual sizes also available on request

- Stainless steel 1.4301, 1.4404, 1.4571

- welded without gaps for a dead space-free mixing process

- Tornado version for use in IBC containers

- Installation in combination with several impeller levels and residual impeller

- individual material according to customer requirements, e.g. Superduplex or Hastelloy

- individual coatings according to customer requirements

More information

Have you found what you’re looking for? We would be happy to show how you can benefit from using the VISCO JET® SPIRAL based on your process requirements!

Similar products

You know about it and want to tackle it?!

… or we’ll call you back:

Nothing is as valuable to us as your time. That is why we are happy to prepare specifically for you. We will call you at your preferred time and clarify your questions. This is how we save your time and make your project successful with VISCO JET® solutions! We look forward to seeing you!