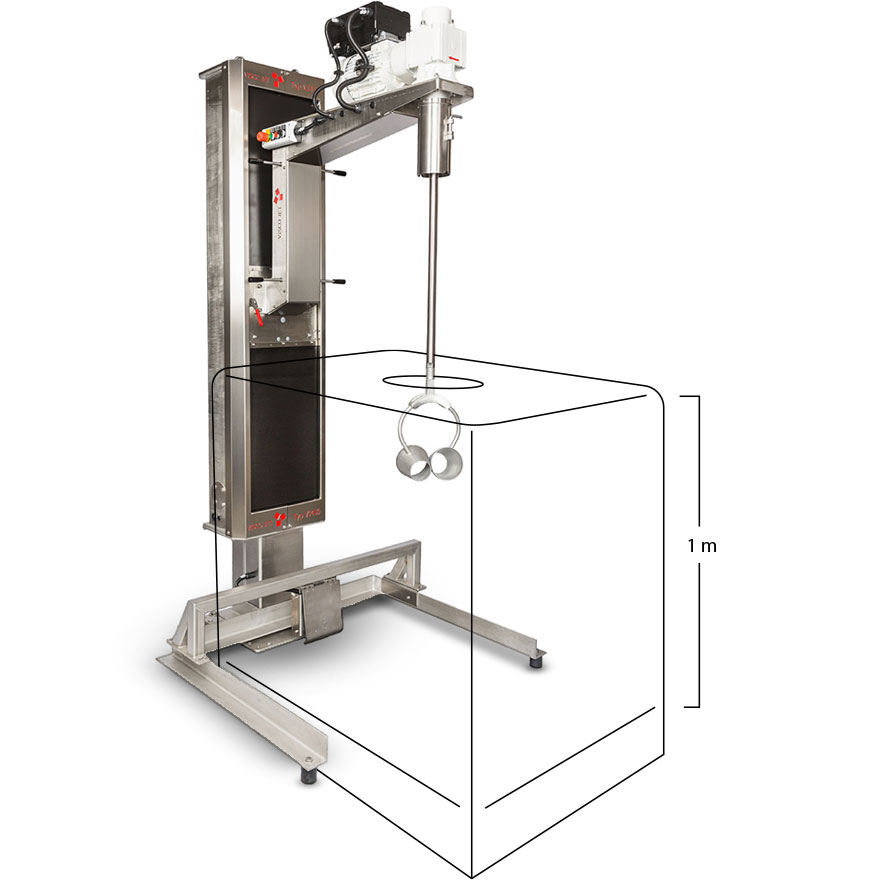

Column agitator for all types of transport containers

Just agitate well

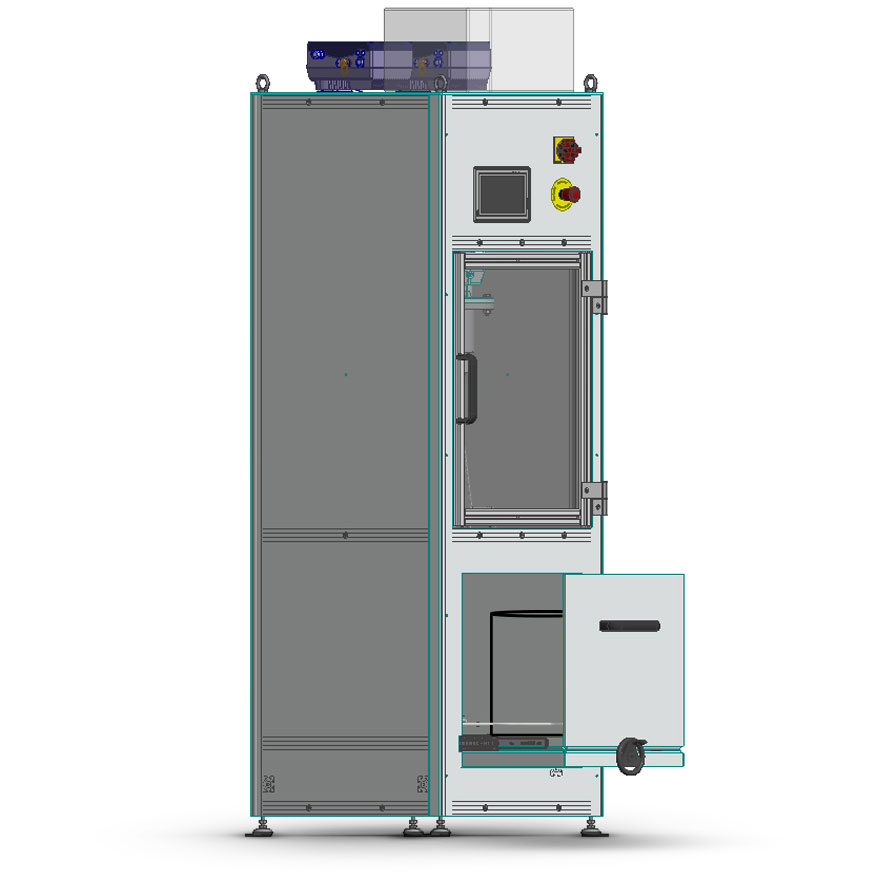

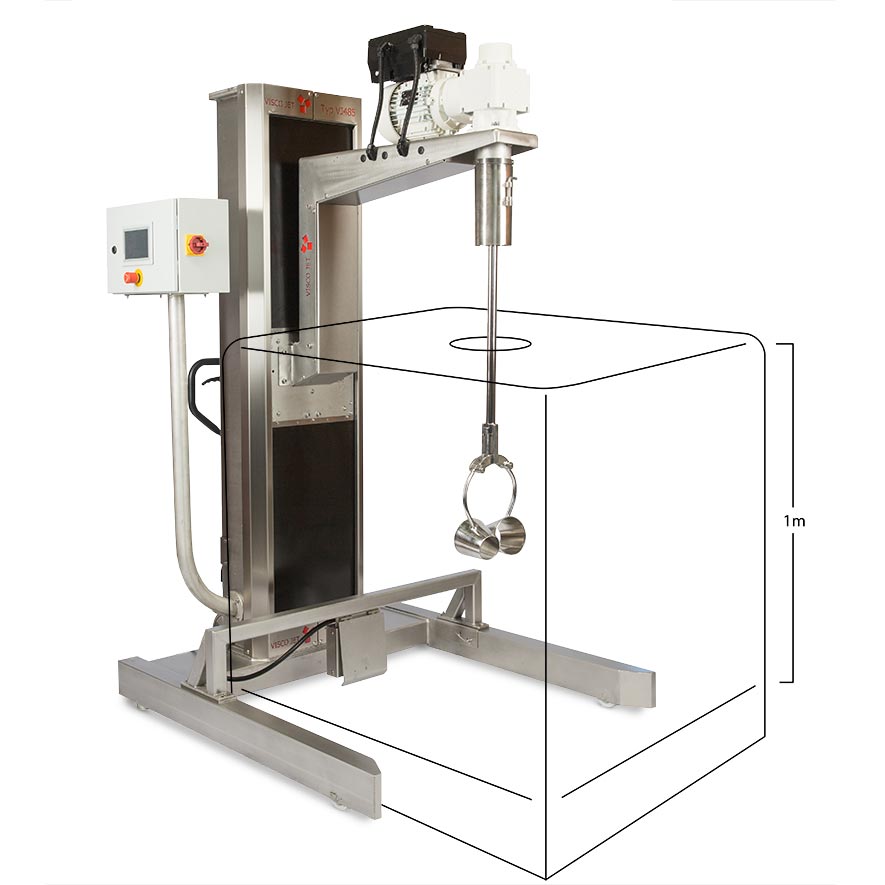

The VISCO JET® VJ450 column agitator with manual height adjustment is the ideal solution for mixing different transport containers such as 1,000 litre IBCs, 200-l plastic drums, hobbocks or customised stainless steel tubs. Different drive variants and mixing elements also enable an efficient and effective solution for the agitating task.

The high-quality stainless steel design as well as the internal lifting mechanism and integrated cable guide facilitate quick and easy cleaning of the agitator and safe operation.

In combination with our switch set and control solutions, it is also possible to control agitation speed, time and even recipe setting and selection.

VJ450 Highlights

The multi-function tool

for increased productivity

Well thought-out, right down to the smallest detail

The VJ450 is a large column agitator that offers maximum flexibility for your manufacturing process.

- Drive power: 1.5 – 3.0 kW

- Speed adjustment by means of a built-on frequency converter

- Power supply: 400 V / 50 Hz incl. plug for plug and play solution

- Lift height adjustment: Manual

- Lift height: 1,200 mm

- Lift fully extended: 1,805 mm

- Retracted: 1,530 mm

- Additional height of the stand base for floor mounting: 450 mm or 900 mm

- Can be mounted directly on a wall using a mounting plate

- Can be mounted directly on the floor by means of a base

- Working position switch

- Container identification

Operation of the agitator is only enabled after positive feedback from the safety switches.

- Column: Stainless steel 1.4301

- Roller belt cover: hard-wearing PUR

- Agitator unit: Stainless steel 1.4404/1.4571

- Can be combined with all VISCO JET® mixing elements

- 2006/42/EU: Machine safety

- 2014/30/EU: Electromagnetic compatibility

- 2014/35/EU: Electrical equipment designed for use within certain voltage limits

- Optional: ATEX version according to RL2014/34/EU

- Quick-release coupling for easy and uncomplicated changing of the mixing units for different containers and agitating tasks without long set-up times

- Ultrasonic sensor for level-dependent speed control

- ATEX design of the agitator for zones 1 in the container according to the requirements of Directive 2014/34/EU

- Individual or standardised lid design as splash protection or for zone separation in ATEX applications (in combination with an extraction system provided by the customer)

- Ratchet belt solution or container clamping for light or smaller containers with very viscous media to mechanically prevent the container from twisting or moving and thus minimise the risk of accidents

- Positioning aid for quick positioning of an IBC in front of the agitator

- Flexibly adjustable container detection and fixation for use with widely varying container diameters to ensure maximum safety for the user

- Ground or electropolished finish of all components in contact with the product with Ra<0.8 µm or Ra<0.4 µm for even easier, faster and safer cleaning

- Different control variants with safety category SIL3, which make the manufacturing process more efficient and reproducible, e.g. by setting the agitating speed and time

- Mounting set for simple, fast and safe installation of the agitator on the floor or wall

Configure your project online now

Sie sehen gerade einen Platzhalterinhalt von Standard. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf den Button unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Weitere InformationenAt home in your industry

More information

Have you found what you’re looking for? We would be happy to show you how you can benefit from using the VJ450 based on your process requirements!

Need more details for your planning? No problem – just tell us what you need!

Similar products

COLUMN AGITATORS: VISCO JET® VJ405

COLUMN AGITATORS: VISCO JET® VJ411

COLUMN AGITATORS: VISCO JET® VJ400

COLUMN AGITATORS: VISCO JET® VJ421

COLUMN AGITATORS: VISCO JET® VJ200

COLUMN AGITATORS: VISCO JET® VJ480

COLUMN AGITATORS: VISCO JET® VJ485

You know about it and want to tackle it?!

… or we’ll call you back:

Nothing is as valuable to us as your time. That is why we are happy to prepare specifically for you. We will call you at your preferred time and clarify your questions. This is how we save your time and make your project successful with VISCO JET® solutions! We look forward to seeing you!