Cut process costs while at the same time increasing output

Cut process costs while at the same time increasing output

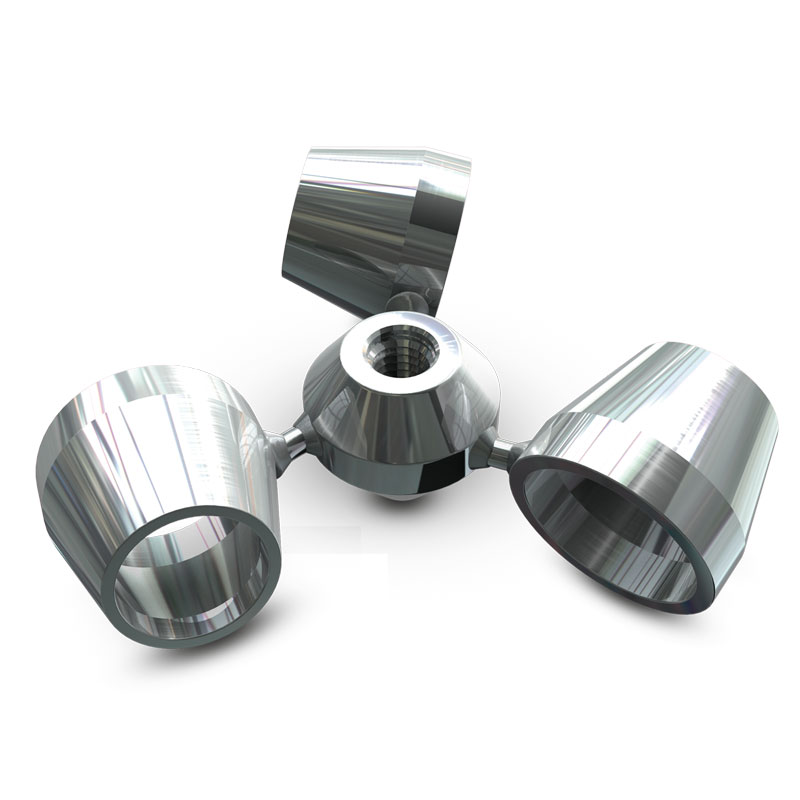

VISCO JET® proves beyond doubt that for successful agitation, mixing, homogenizing, suspending, or dispersing, it’s not the speed that’s decisive, but the technique. Its particular strength lies in the special geometry of the conical mixing elements.

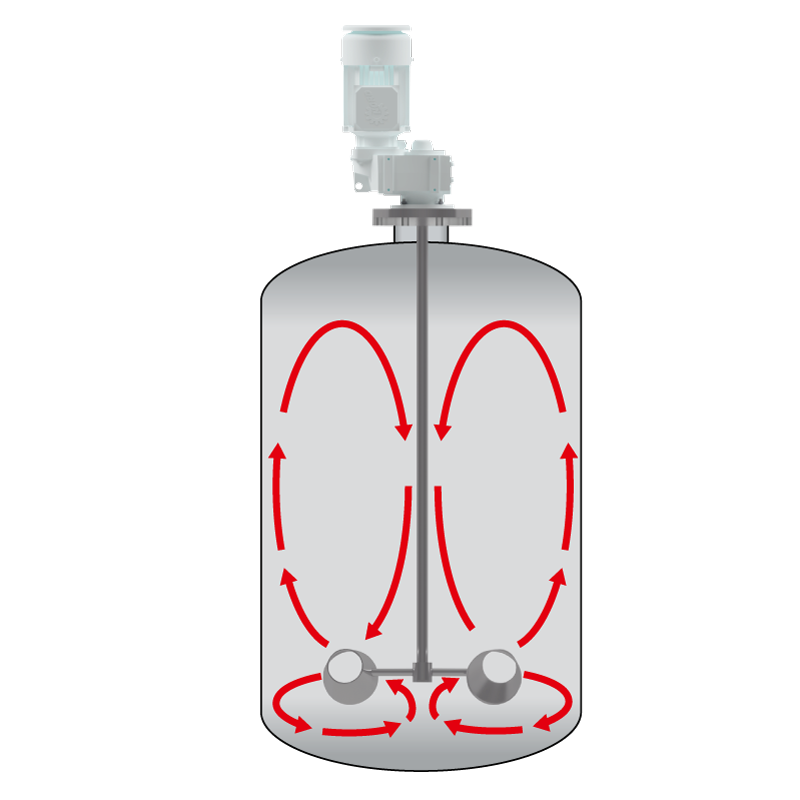

With its cleverly designed spatial and angular relationships, the agitator ensures an optimum mixing process in a very short time, even at the lowest peripheral speeds.

We‘ve proven this technology in almost every industry. It is versatile, reduces costs and guarantees high-quality results.

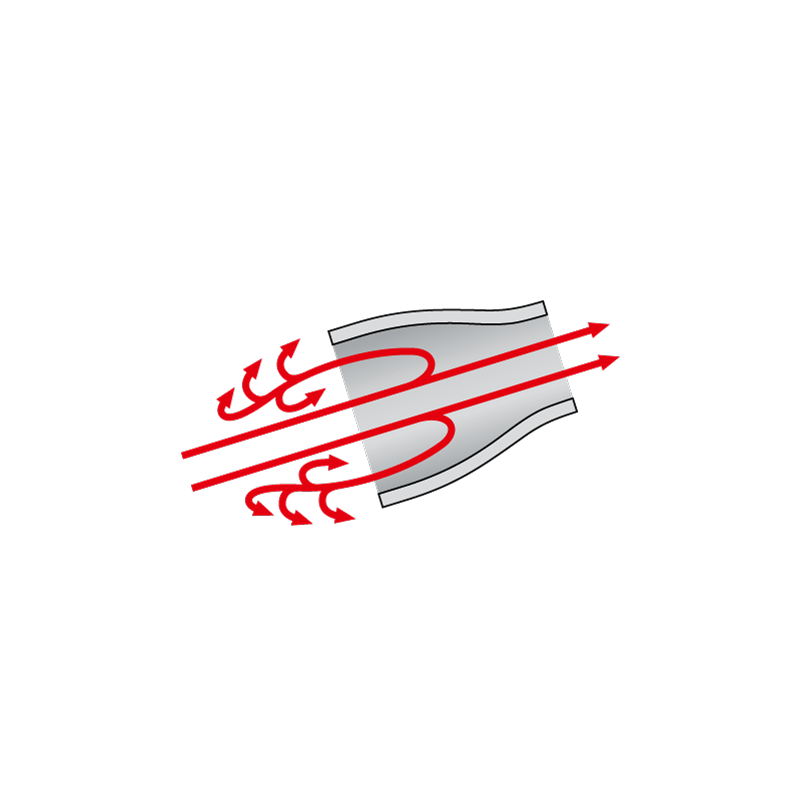

Accelerated laminar flows at the cone exit and the reverse turbulence created by dynamic pressure at the cone entrance interact as the agitator rotates, generating high-momentum mixing movements.

The extremely material-friendly and highly efficient agitator makes it possible to mix, agitate, homogenize, disperse, and suspend with very little energy expenditure. This applies particularly to tanks with very high volumes.

Nothing is as valuable to us as your time. That is why we are happy to prepare specifically for you. We will call you at your preferred time and clarify your questions. This is how we save your time and make your project successful with VISCO JET® solutions! We look forward to seeing you!

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information