We deliver sustainable solutions together with service and training

Our products and complete solutions

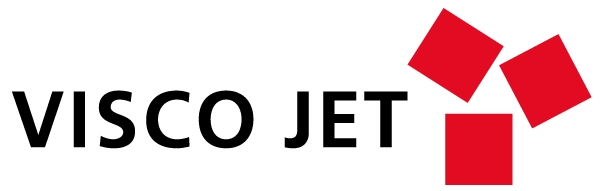

Laboratory and pilot plant agitators

Our VISCO JET® laboratory and pilot plant agitators are small, powerful, and efficient. In laboratories, mixing tests are initially carried out on a small scale during the development phase. Our laboratory and pilot plant agitators are designed specifically for the application and offer the greatest possible flexibility for day-to-day operations in the laboratory.

Drive powers of 0.12-0.55 kW for an individual and sustainable solution to the agitating task, even with highly viscous media

Can be combined with all VISCO JET® impeller solutions for optimum stirring results

For small to medium-sized containers such as buckets with a diameter of up to 400 mm and a height of up to 500 mm

The lift height can be adjusted quickly and easily via a handle on the base arm.

Agitator shaft with convenient quick-release coupling or quick-release chuck

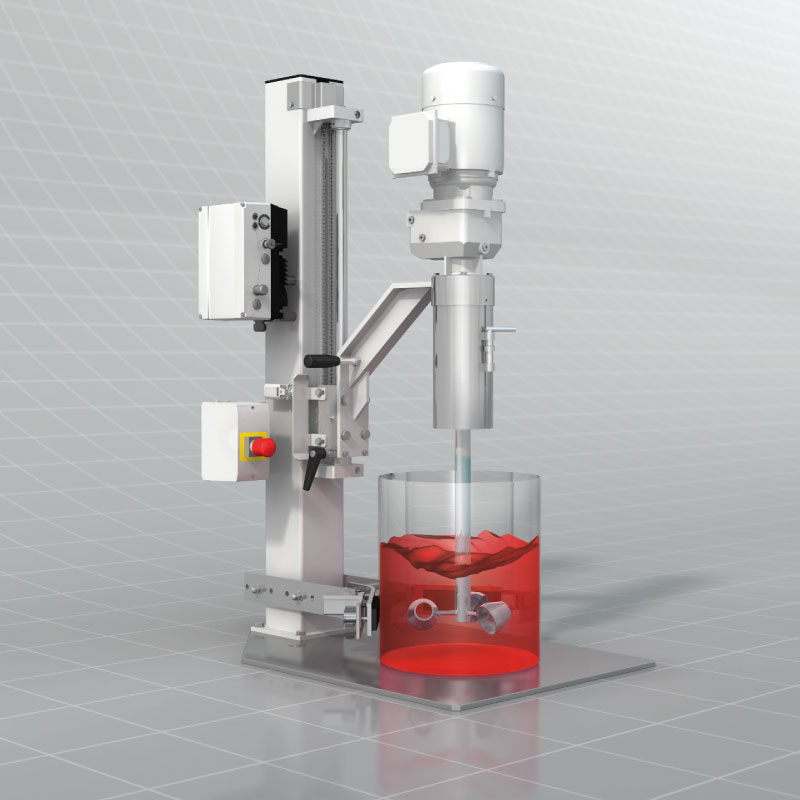

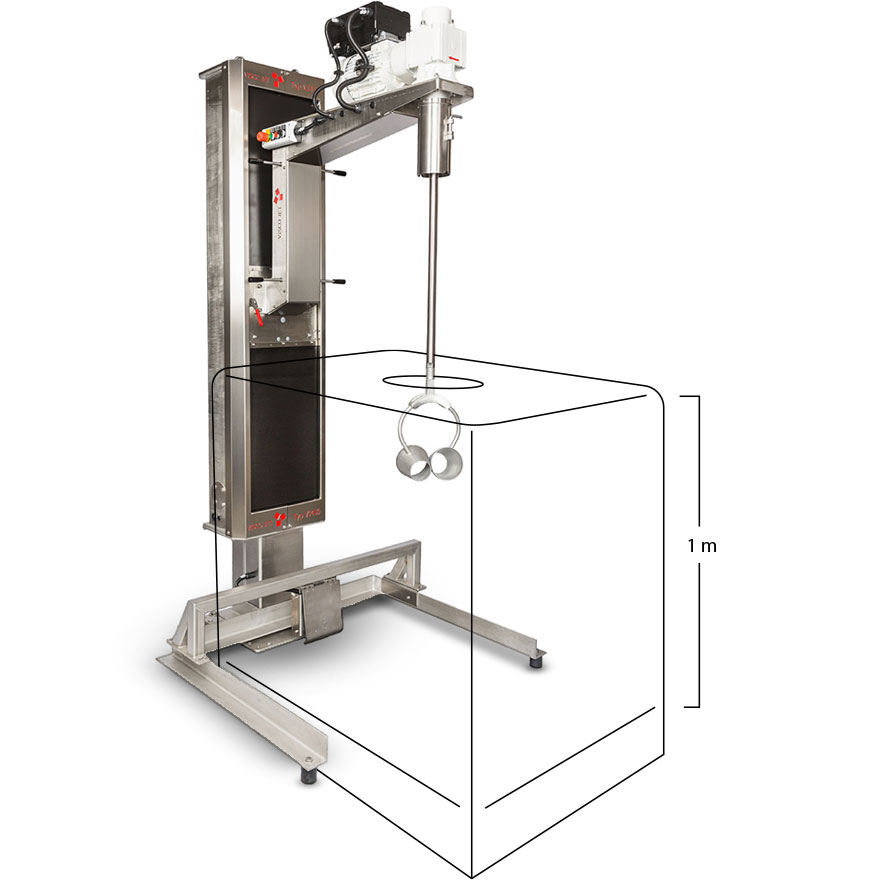

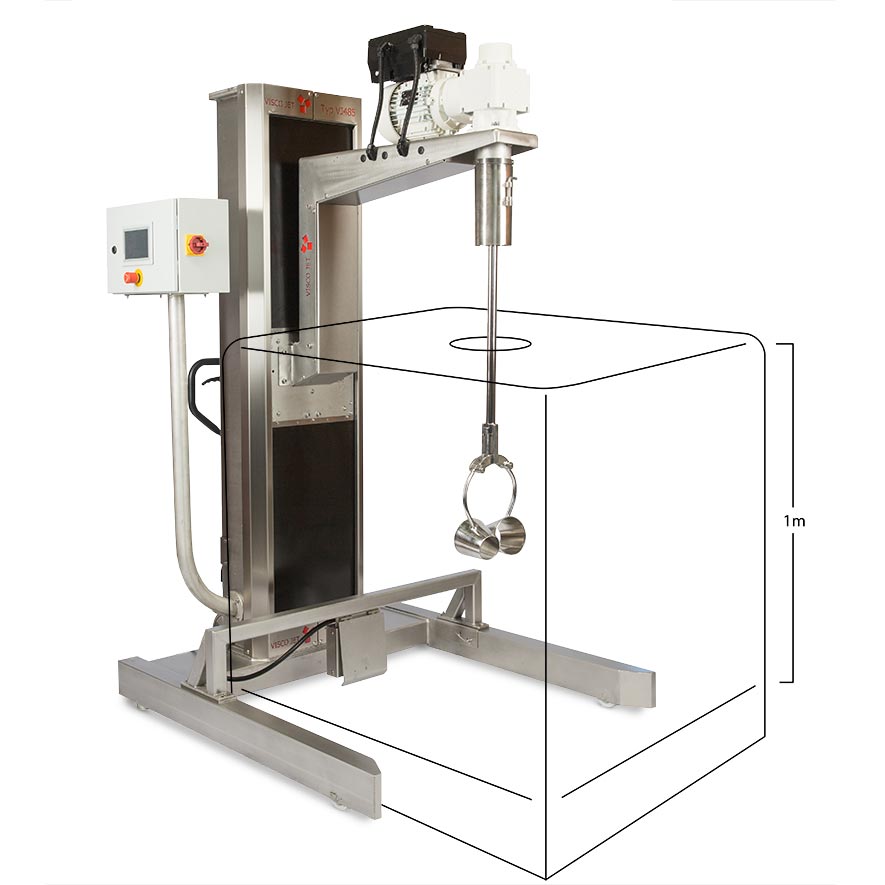

Container and drum agitators

Our container and drum agitators can agitate media with up to 30,000 mPas in IBC containers and standard 200-litre drums before further processing or process them efficiently and sustainably in the container itself.

Drive power up to 3 kW for a customized and sustainable solution to the stirring task

Special Tornado or Mistral mixing element for openings with DN 150 mm or bung hole

For standard 600-l or 1,000-l IBC containers and standard 200-l drums

With traverse system to mounting the agitator directly on the container

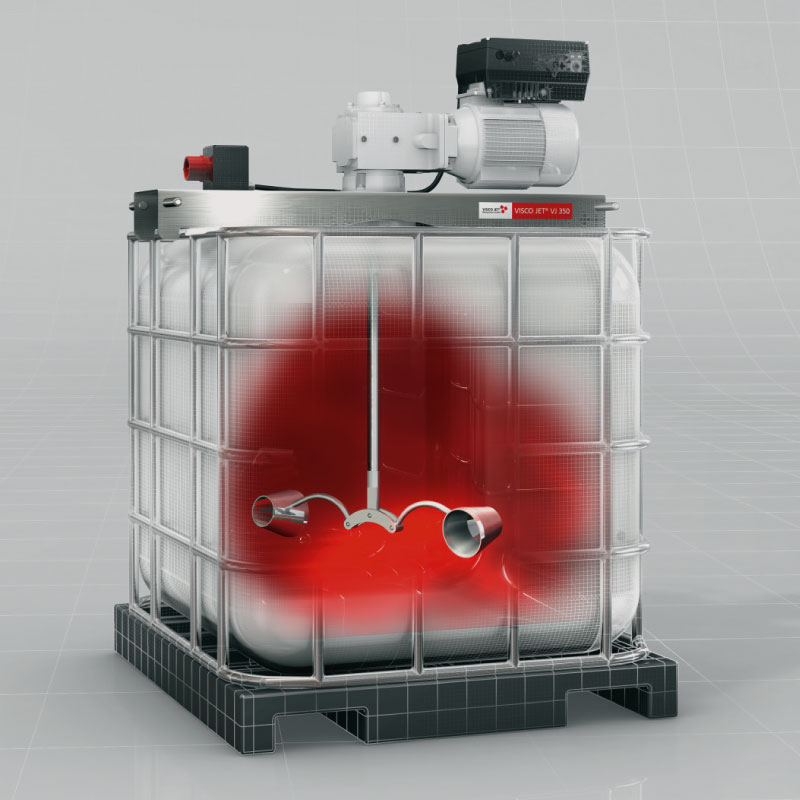

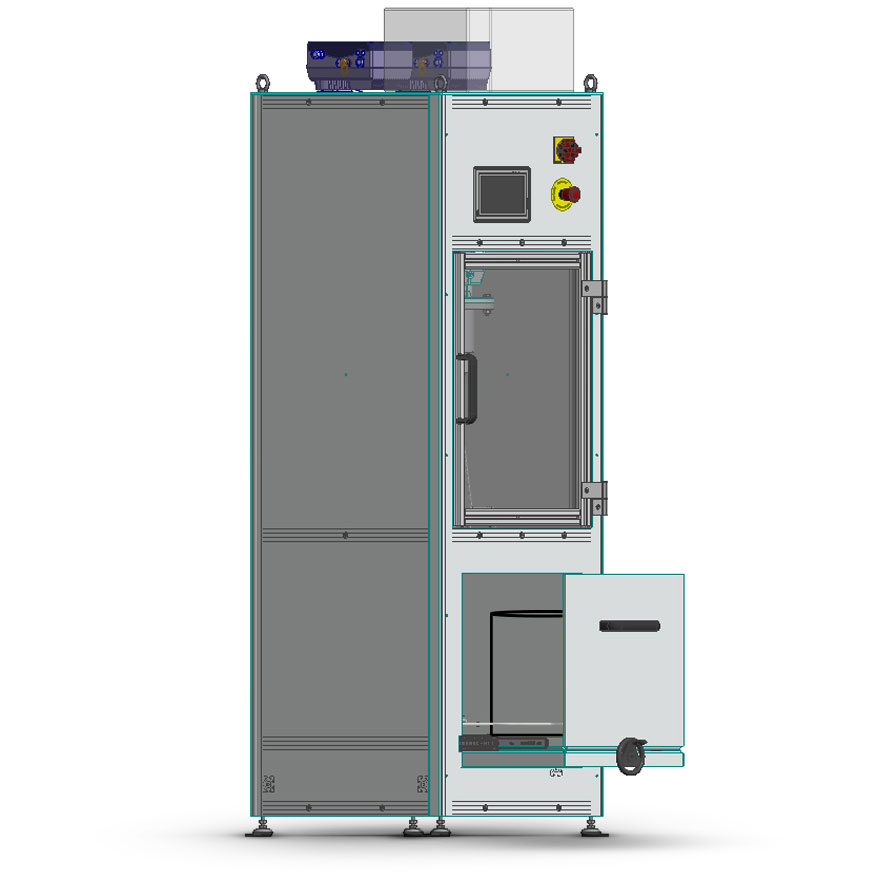

Column agitators

Our column agitators are able to safely agitate various container sizes and geometries, different filling volumes and products with the greatest degree of flexibility.

Various drive powers from 1.1-11 kW are available for individual and sustainable agitator solutions

Can be combined with all VISCO JET® impeller solutions for optimum stirring results with consistent product quality over the long term

Agitator shaft with convenient quick-release coupling

Wall, floor or mobile column version possible. Agitator is easy to convert, making it ready for use again immediately

A lift height of up to 1,800 mm allows maximum flexibility when agitate different container sizes, such as 1,000-l or 600-l IBCs, 200-l stainless steel or plastic drums, hobbocks, stainless steel or plastic tubs as well as customised containers with an internal height of up to 1,600 mm

Manual or electric lift height adjustment for the greatest degree of operating comfort

High-quality painted or stainless steel column for quick and easy cleaning without long downtimes during the production process

High level of safety during agitator operation thanks to the integrated working position switch and container detection on the stand base

Tank agitators

VISCO JET® tank agitators are designed for permanently installed storage or production tanks from 10 litres to 1.5 million litres and can be individually adapted to the customer’s needs. During development and engineering, we focus on process optimisation, safety, sustainability and ease of maintenance in order to offer an efficient solution for the further development of products and processes in all industries.

Customised agitator solutions from a single source regardless of tank shape or volume

Sustainable and energy-efficient agitator solution thanks to a slow-running agitator system with low drive power

Can be combined with all VISCO JET® impeller solutions for optimum agitating results with consistent quality over the long term

Various sealing solutions for a high degree of product and occupational safety

Low wear of the agitator components due to low speeds and easy maintenance

Agitator easy to clean (also suitable for CIP solutions)

Simple assembly and commissioning – designed and manufactured for rapid use by the customer

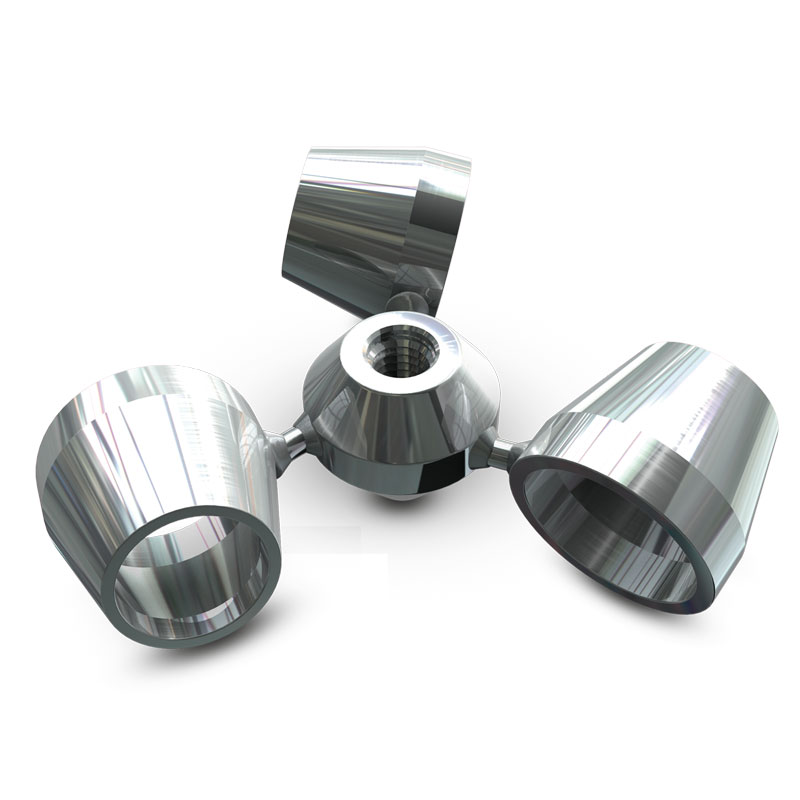

Mixing elements / Impellers

Various versions and sizes of our VISCO JET® impellers are in use. They are either all-rounders or specialists, depending on the agitation application and the medium. They are the spearhead of sustainable agitation.

But VISCO JET® is so much more. We have optimised the entire value chain for sustainability. This benefits our customers day after day in three ways: consistent quality, more efficient processes and lower energy consumption.