Very effective on the production line

Powerful stirring when producing colour shades for facade paints and plaster

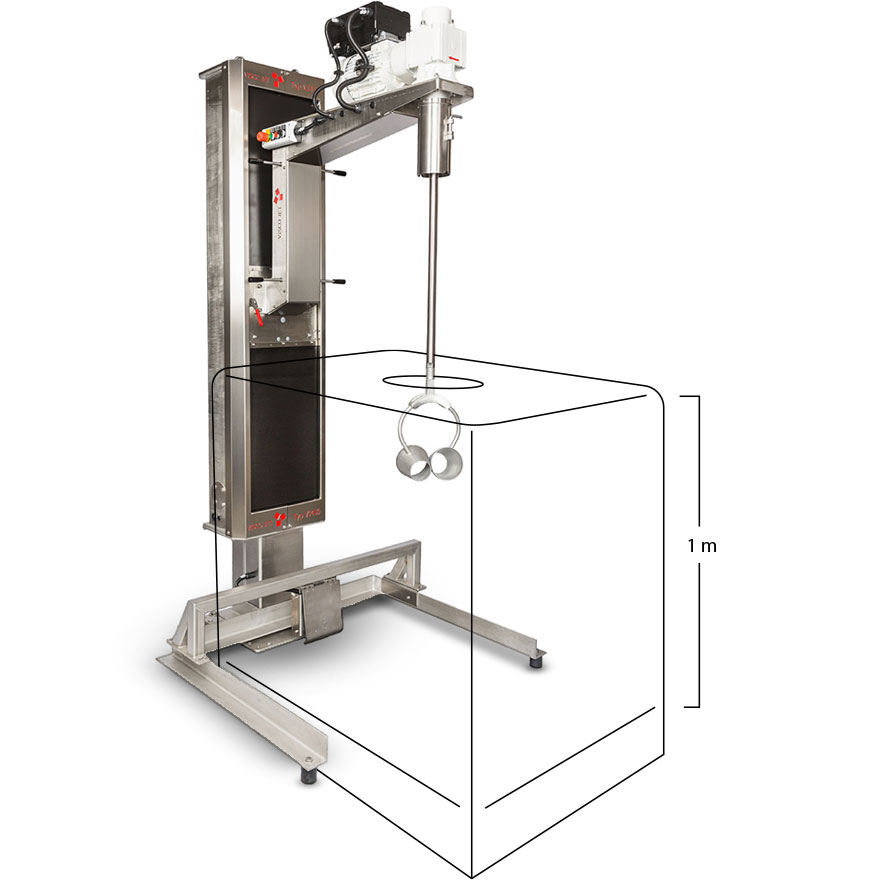

You can achieve maximum efficiency and flexibility in the production of individual colour shades in small containers with the VISCO JET® VJ405!

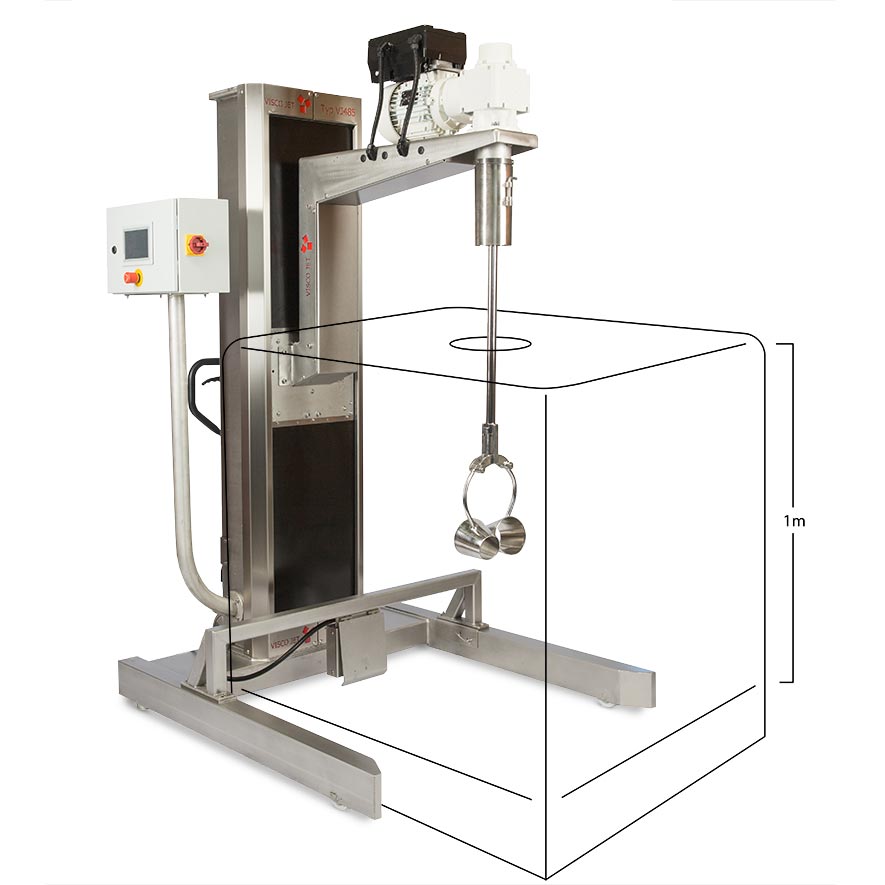

Developed for professional use in continuous operation and in combination with a roller track, this innovative device is perfect for mixing and producing colour shades for facade paints and plaster in round and oval containers. Different design options offer you maximum flexibility and safety.

Invest in the future of your business and increase your productivity with the VISCO JET® VJ405!

VJ405 Highlights

The multi-function tool

for increased productivity

Well thought-out, right down to the smallest detail

Simple operation for optimal integration into your production process

- The container is fed into the agitator via a roller track

- Container reaches the mixing position

- Fixing of the container via manual or optional pneumatic and automated container clamping

- The drip tray swivels to the side

- Selection of the agitating programme via touch screen or master control

- Agitating process is started

- Agitated process is finished

- Container is released, drip tray swivels back

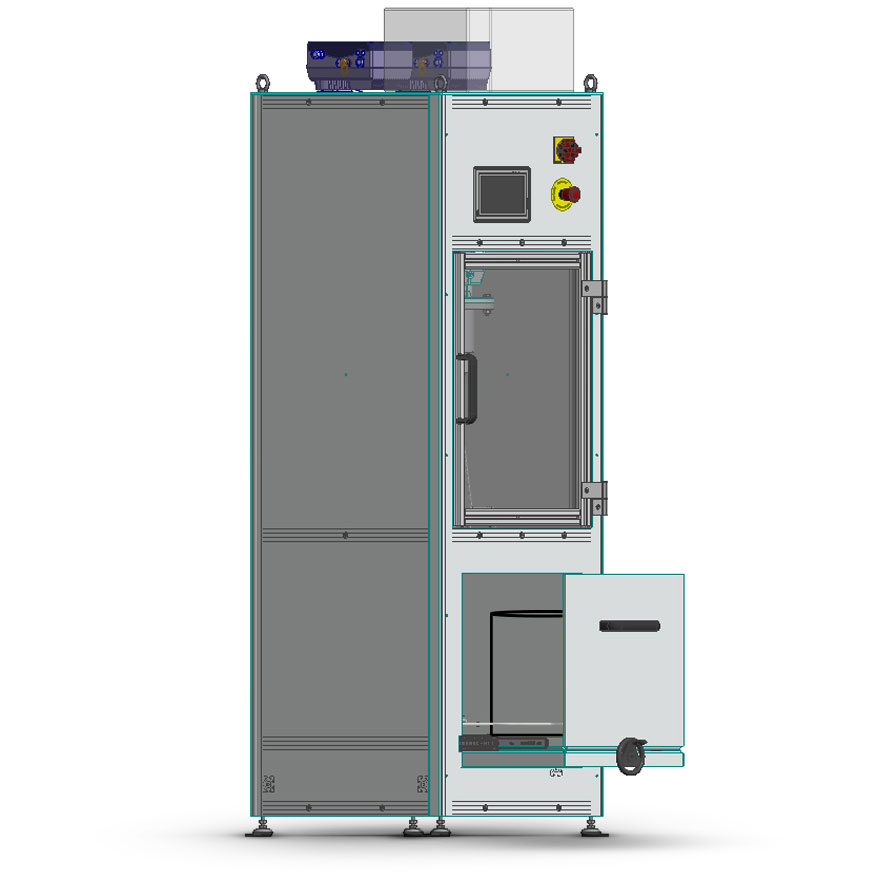

- Drive power 2.2 kW

- Power: 400 V incl. high-voltage power supply

- Lift height adjustment: Electric

- Lift height: 500 mm

- Dimensions 2,341 x 906 x 1,030 mm

- Working and end position switches

- Door with safety switch

- Container clamping

- Safety enclosure with maintenance access and viewing window

- Stand material: Aluminium and stainless steel profile construction

- Agitator unit: Stainless steel 1.4404/1.4571

- Stainless steel safety enclosure

- Aluminium housing profile

- Recipe management with 10 programs incl. setting the agitatinig time and speed and the agitating position

VISCO JET® PYRAMIDE

After a very short time, optimum colour shades and viscosity of the mixed medium are produced during the agitating process using VISCO JET® PYRAMIDE agitator specially developed for this application.

The agitator unit is also equipped with quick-release coupling.

- 2006/42/EU: Machine safety

- 2014/30/EU: Electromagnetic compatibility

- 2014/35/EU: Electrical equipment designed for use within certain voltage limits

- Additional agitator units

- Position measurement system for individual height adjustment of the stirring position

- Integration with the customer’s master control system

- Pneumatic container clamp

- Lateral tamper protection

- Roller track

Configure your project online now

Sie sehen gerade einen Platzhalterinhalt von Standard. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf den Button unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Weitere InformationenAt home in your industry

More information

Have you found what you’re looking for? We would be happy to show you how you can benefit from using the VJ405 based on your process requirements!

Need more details for your planning? No problem – just tell us what you need!

Need more details for your planning? No problem – just tell us what you need!

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSimilar products

COLUMN AGITATORS: VISCO JET® VJ421

COLUMN AGITATORS: VISCO JET® VJ200

COLUMN AGITATORS: VISCO JET® VJ450

COLUMN AGITATORS: VISCO JET® VJ411

COLUMN AGITATORS: VISCO JET® VJ400

COLUMN AGITATORS: VISCO JET® VJ480

COLUMN AGITATORS: VISCO JET® VJ485

You know about it and want to tackle it?!

… or we’ll call you back:

Nothing is as valuable to us as your time. That is why we are happy to prepare specifically for you. We will call you at your preferred time and clarify your questions. This is how we save your time and make your project successful with VISCO JET® solutions! We look forward to seeing you!