Semi-automatic column agitator for the point of sale

Specialist for paints and plasters

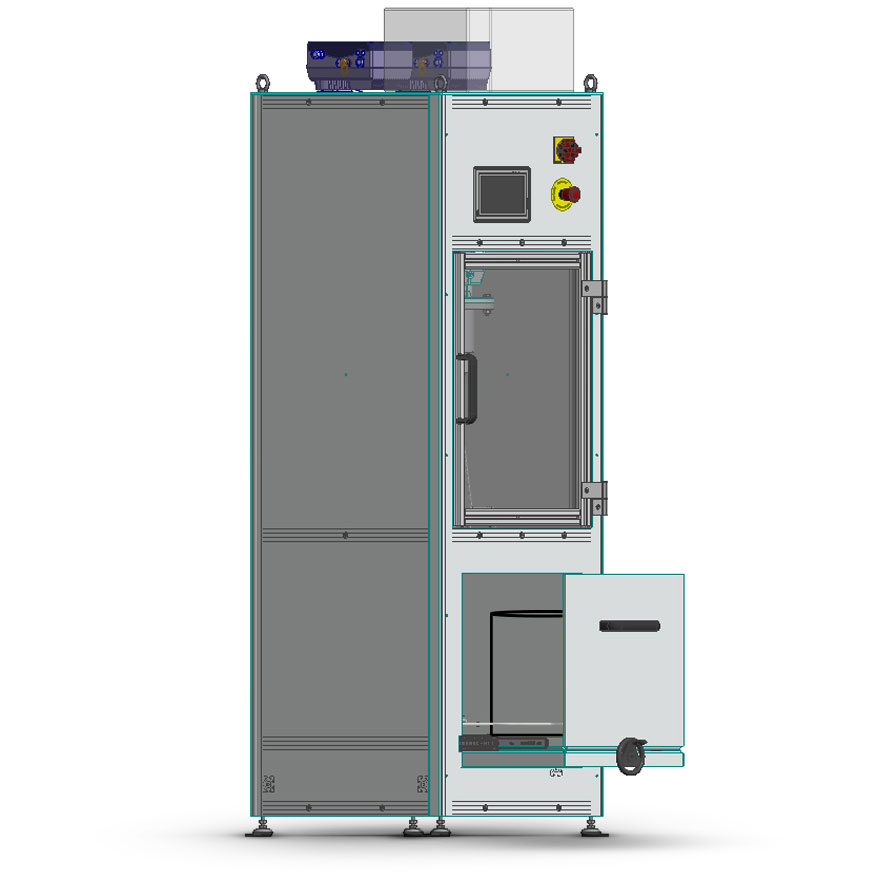

The VISCO JET® VJ411 was specially developed for agitating and producing colour shades in facade paints in round and oval containers with a capacity of 5 to 30 litres. The container is inserted into the agitator via a drawer and fixed by means of a manual container clamp.

The agitator has VISCO JET® quick-release coupling, which allows the mixing element to be changed easily, and is equipped with the VISCO JET® PYRAMIDE impeller. A drip tray system additionally prevents soiling of the container support.

The digital control unit and programming of agitating processes via an integrated touch screen make the VISCO JET® VJ411 easier to handle and create reproducible processes.

VJ411 Highlights

The multi-function tool

for increased productivity

Well thought-out, right down to the smallest detail

Simple operation for optimal integration into your process

- The container is placed on the container support of the drawer

- Fixation of the container via manual container clamping using a hand wheel

- The user closes the drawer

- The drip tray swivels to the side

- The agitating programme is selected via touch screen

- Agitating process is started

- Agitating process is finished

- The drawer is opened

- The drip plate swings back

- The container fixation is loosened manually and removed

- Drive power 1.1 kW

- Power: 400 V incl. high-voltage power supply

- Lift height adjustment: Electric

- Lift height: 400 mm

- Dimensions 2,066 x 761 x 532 mm

- Working and end position switches

- Drawer with safety switch

- Container clamping

- Safety enclosure with maintenance access and viewing window

- Column material: Aluminium and stainless steel profile construction

- Agitator unit: Stainless steel 1.4404/1.4571

- Stainless steel safety enclosure

- Aluminium housing profile

- Recipe management with 10 programs incl. setting the agitating time and speed

VISCO JET® PYRAMIDE

After a very short time, optimum colour shades and viscosity of the agitating medium are produced during the stirring process using VISCO JET® PYRAMIDE mixing element specially developed for this application.

The agitator unit is also equipped with quick-release coupling.

- 2006/42/EU: Machine safety

- 2014/30/EU: Electromagnetic compatibility

- 2014/35/EU: Electrical equipment designed for use within certain voltage limits

- Additional agitator units

Configure your project online now

Sie sehen gerade einen Platzhalterinhalt von Standard. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf den Button unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Weitere InformationenAt home in your industry

More information

Have you found what you’re looking for? We would be happy to show you how you can benefit from using the VJ411 based on your process requirements!

Need more details for your planning? No problem – just tell us what you need!

Similar products

COLUMN AGITATORS: VISCO JET® VJ450

COLUMN AGITATORS: VISCO JET® VJ405

COLUMN AGITATORS: VISCO JET® VJ400

COLUMN AGITATORS: VISCO JET® VJ421

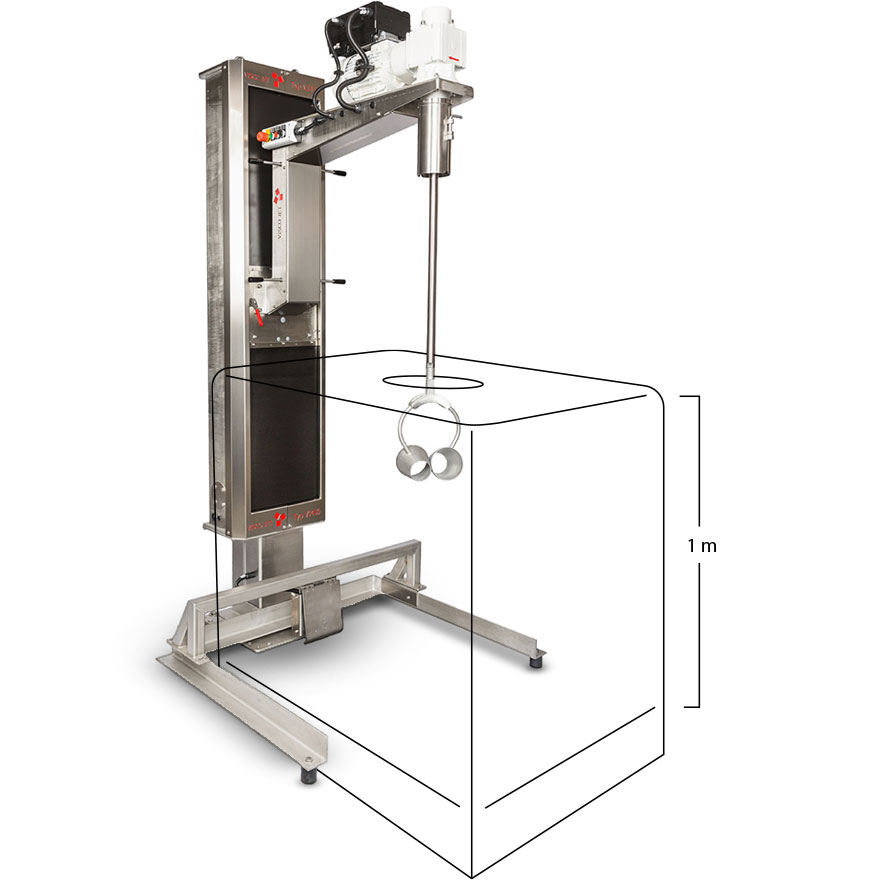

COLUMN AGITATORS: VISCO JET® VJ200

COLUMN AGITATORS: VISCO JET® VJ480

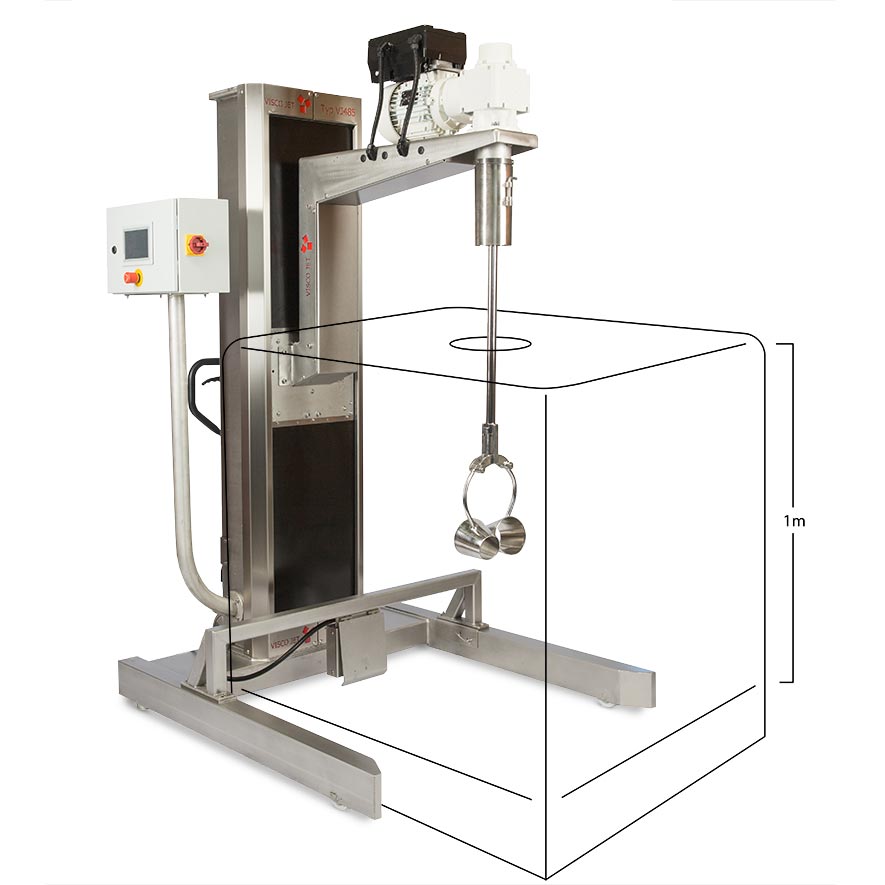

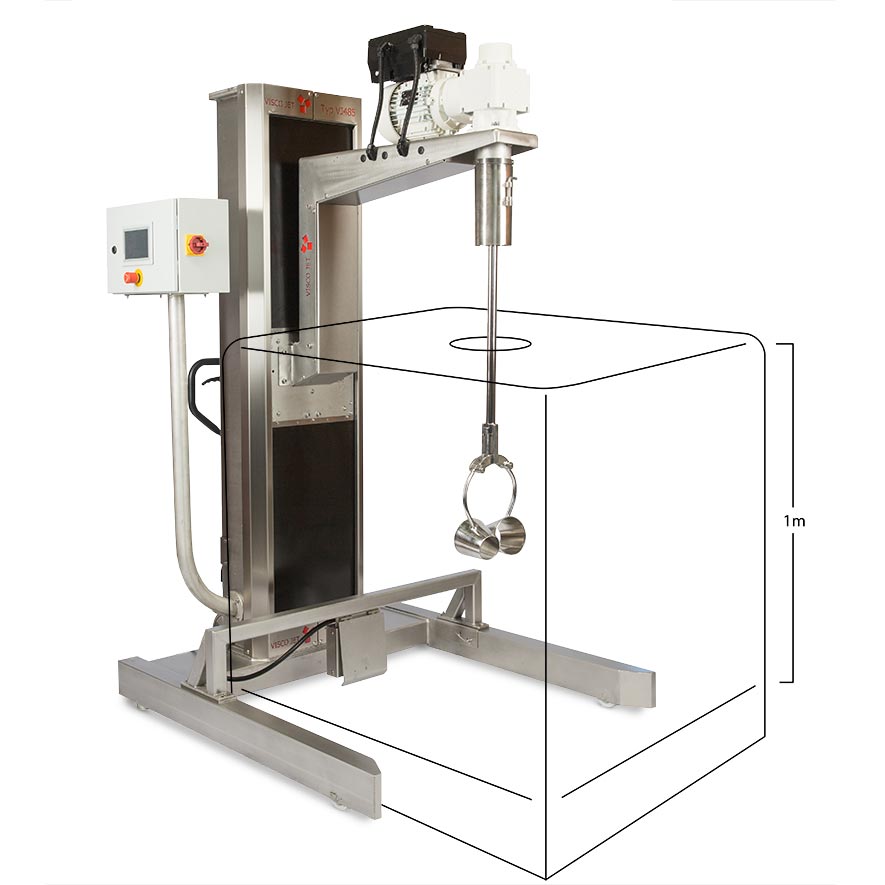

COLUMN AGITATORS: VISCO JET® VJ485

You know about it and want to tackle it?!

… or we’ll call you back:

Nothing is as valuable to us as your time. That is why we are happy to prepare specifically for you. We will call you at your preferred time and clarify your questions. This is how we save your time and make your project successful with VISCO JET® solutions! We look forward to seeing you!